Material: Polypropylene (PP)

Diaphragm / valve balls / seals material: PTFE / PTFE / PTFE

Note: The pump types DMP 1" PPT PP/PTFE and DMP 1" KNT PVDF/PTFE are also available in the Pure version. The pumps are used in particular in the food and cosmetics industry as well as in the pharmaceutical industry.

Pure version:

| Pump type | Materials | Order no. | ||

|---|---|---|---|---|

| Diaphragm | Valves | Seals | ||

| Surcharge DMP 1" PPT PP/PTFE PURE | PTFE | PTFE | PTFE | 5000-641 |

*Please select order no. basic pump + order no. PURE additional price

Description:

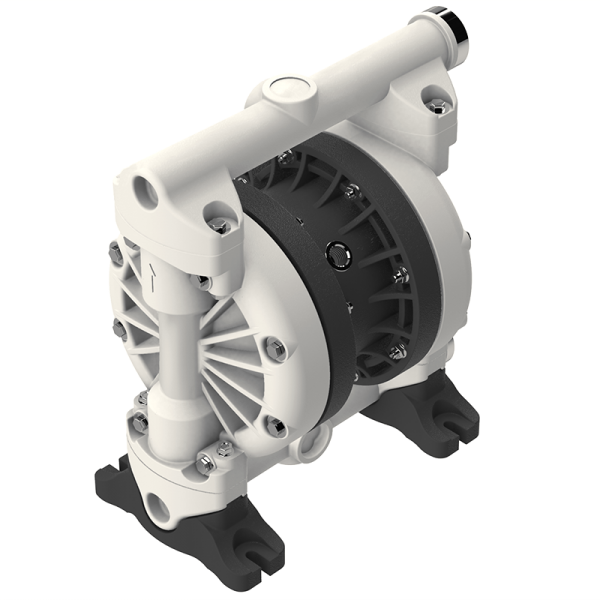

The double diaphragm pump is suitable for industrial applications as well as for emptying drums, IBCs and tanks.

- typical applications: Transfer from drums and containers, transfer of corrosive solutions and chemicals

- integrated muffler up to model size AODD 1"

- highly resistant TFM (PTFE) diaphragms (modified PTFE)

Features & Benefits

- high hydraulic performance

- maintenance-optimised design and simple installation

- self-priming (even when dry)

- reinforced elastomers and thermoplastic diaphragms

- absolutely oil-free

- non-stalling operation

| Double diaphragm pumps (material): | non - metallic |

| Housing (material): | Polypropylene glass fibre reinforced (PP) |

| Centre block (material): | Polypropylene carbon fibre reinforced (PP) |

| Diaphragms (material): | FPM (fluorinated rubber) |

| Valve ball (material): | FPM (fluorinated rubber) |

| Seals (material): | FPM (fluorinated rubber) |

| Valve seat (material): | PP (polypropylene) |

| Delivery rate (up to max. l/min)*: | 175 |

| Delivery head (up to max. mWS)*: | 80 |

| Solids (max. ø mm): | 6,0 |

| Fluid temperature (max °C): | 60 |

| Viscosity (up to mPas): | 10000 |

| Suction head dry (up to max. mwc*): | 4,5 |

| Air pressure (max. bar): | 8 |

| Air pressure start-up (min. bar): | 2 |

| Sound pressure level dB(A): | 80 |

| Displacement per chamber (in cm³): | 220 |

| Displacement per chamber (in cm³): | 440 |

| Size: | 1" |

| Air inlet (inch) inside: | 3/8" |

| Pressure joint (inch) inside: | 1" |

| Suction joint (inch) inside: | 1" |

| Explosion protection: | No |

| Connection: | Gewinde |

| Type: | DMP 1" PPV PP/FPM |

* The maximum flow rate is a value determined by means of a test bench and measured with water at a medium temperature of approx. 20 °C. The measurement is carried out at the pressure joint of the pump, without hose, nozzle or flow meter. The achievable flow rate in use is lower and depends on the individual application, the liquid properties and the configuration of the pump. The max. delivery head also depends on the pump design, motor and fluid. The viscosity values are determined with oil. ** Test assembly: Medium water / diesel, flow in preferred direction, settling section 0.2 m upstream and downstream of flow meter